Stainless steel is a cornerstone in modern manufacturing, especially in the production of floor drain covers. This material’s durability, resistance to corrosion, and aesthetic appeal make it an ideal choice for environments demanding hygiene and longevity. In this comprehensive guide, we will explore the material science behind stainless steel, its application in floor drain cover production, and the advanced techniques that make this combination so effective.

The Basics

Stainless steel is an alloy primarily composed of iron, carbon, and chromium. The addition of chromium, typically at a minimum of 10.5%, gives stainless steel its remarkable resistance to corrosion. This resistance is due to the formation of a passive layer of chromium oxide on the surface, which prevents further oxidation and corrosion. Other elements like nickel, molybdenum, and nitrogen can be added to enhance specific properties such as strength, ductility, and resistance to pitting and crevice corrosion.

Types of Stainless Steel

There are several types of stainless steel, each with distinct properties suited for different applications:

- Austenitic Stainless Steel: Known for its excellent corrosion resistance and good formability. Common grades include 304 and 316, with 316 offering higher resistance to chloride corrosion, making it ideal for marine environments and floor drain covers in wet areas.

- Ferritic Stainless Steel: Less ductile but more resistant to stress corrosion cracking. Grades like 430 are often used in automotive applications and less demanding environments.

- Martensitic Stainless Steel: Known for its high strength and hardness but lower corrosion resistance. Grades such as 410 and 420 are used in cutlery and tools.

- Duplex Stainless Steel: Combines the best properties of austenitic and ferritic stainless steels, offering high strength and excellent resistance to stress corrosion cracking. Grades like 2205 are used in chemical processing and marine applications.

Stainless Steel in Floor Drain Cover Production

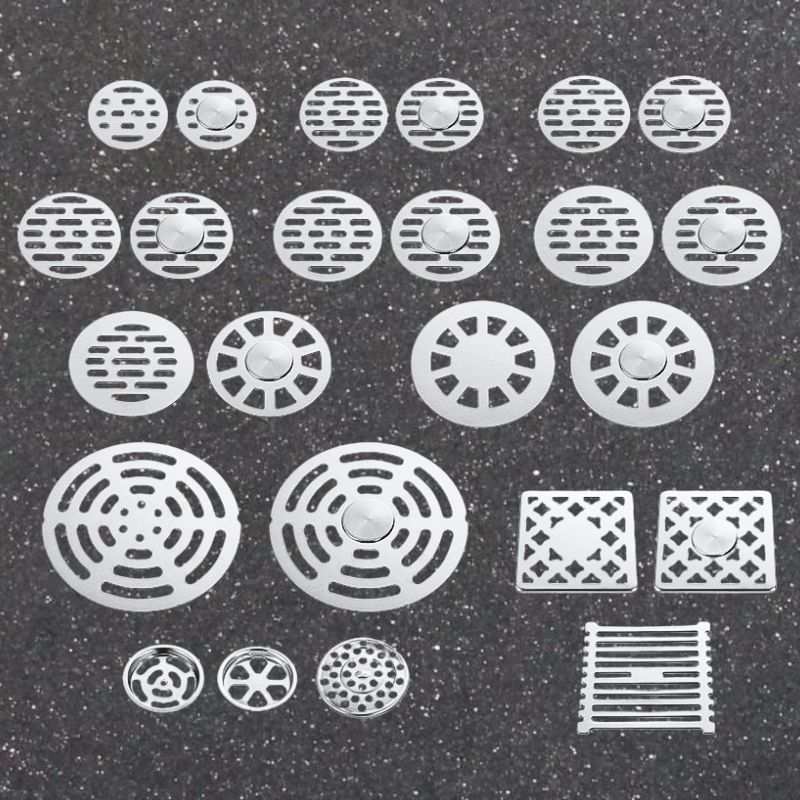

The use of stainless steel in floor drain cover production leverages its unique properties to create products that are not only functional but also durable and visually appealing. These covers are essential in various settings, from commercial kitchens to industrial plants, ensuring effective drainage and preventing debris from clogging the drainage system.

Benefits of Stainless Steel Floor Drain Covers

Stainless steel floor drain covers offer numerous benefits:

- Corrosion Resistance: Ideal for wet environments, stainless steel prevents rust and extends the product’s lifespan.

- Durability: Withstands heavy loads and high traffic without deforming or breaking.

- Hygiene: Easy to clean and maintain, crucial for food processing and healthcare facilities.

- Aesthetic Appeal: Provides a sleek, modern look that can be customized to fit various design preferences.

Production Techniques

The production of stainless steel floor drain covers involves several advanced techniques to ensure precision and quality.

CNC Perforation

Computer Numerical Control (CNC) perforation is a key technique in the production of stainless steel floor drain covers. CNC machines use pre-programmed software to control the movement and operation of the tools. This process ensures high precision and consistency, allowing for complex designs and patterns that would be difficult to achieve manually.

- Advantages of CNC Perforation:

- High precision and accuracy.

- Ability to produce intricate and complex patterns.

- Consistent quality with minimal human error.

- Efficient use of materials, reducing waste.

Laser Cutting

Laser cutting is another crucial technique used in the production of stainless steel floor drain covers. This method uses a focused laser beam to cut through the material with high precision.

- Benefits of Laser Cutting:

- High accuracy and clean edges.

- Minimal heat-affected zones, preserving the material’s properties.

- Flexibility in cutting various shapes and sizes.

- Faster production times compared to traditional cutting methods.

Material Science in Production

Understanding the material science behind stainless steel helps manufacturers optimize the production process and improve the quality of floor drain covers.

Metallurgical Properties

The metallurgical properties of stainless steel, such as its microstructure and phase composition, play a crucial role in determining its performance. For instance, the austenitic structure of 304 and 316 stainless steels provides excellent toughness and formability, making them suitable for complex designs and harsh environments.

Surface Treatments

Surface treatments can enhance the performance and appearance of stainless steel floor drain covers. Common treatments include:

- Passivation: Enhances corrosion resistance by removing free iron from the surface and promoting the formation of the passive chromium oxide layer.

- Electropolishing: Provides a smooth, reflective surface that is easier to clean and offers improved corrosion resistance.

- Powder Coating: Adds a protective and decorative layer, available in various colors and finishes.

Applications of Stainless Steel Floor Drain Covers

Stainless steel floor drain covers are used in a wide range of applications, each with specific requirements and challenges.

Commercial Kitchens

In commercial kitchens, hygiene is paramount. Stainless steel floor drain covers prevent food particles and debris from clogging the drains while being easy to clean and sanitize. The corrosion resistance of stainless steel ensures long-term performance in the presence of water and cleaning chemicals.

Industrial Plants

Industrial plants often deal with heavy machinery and high traffic, requiring durable and robust floor drain covers. Stainless steel’s strength and load-bearing capacity make it suitable for these demanding environments. Additionally, its resistance to chemicals and oils ensures that the covers remain functional and safe.

Healthcare Facilities

Healthcare facilities require sterile environments to prevent infections. Stainless steel floor drain covers provide a hygienic solution that is easy to maintain and disinfect. The material’s resistance to corrosion and staining ensures that it remains in good condition, even with frequent cleaning and exposure to harsh chemicals.

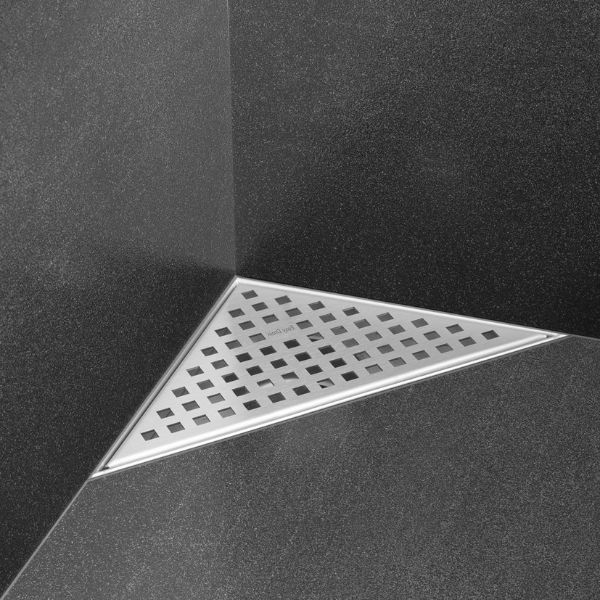

Public Spaces

In public spaces such as shopping malls, airports, and parks, floor drain covers must be both functional and aesthetically pleasing. Stainless steel offers a sleek and modern look that blends well with various architectural styles. Its durability ensures that the covers can withstand high foot traffic and environmental exposure without deteriorating.

Environmental Impact and Sustainability

Stainless steel is an environmentally friendly material due to its recyclability and longevity. Using stainless steel for floor drain covers contributes to sustainable practices in several ways.

Recyclability

Stainless steel is 100% recyclable, meaning that it can be melted down and reused without losing its properties. This reduces the need for virgin materials and lowers the environmental impact of production. Many manufacturers use recycled stainless steel in their products, further promoting sustainability.

Longevity

The durability and corrosion resistance of stainless steel mean that products made from this material have a long lifespan. This reduces the frequency of replacements and the associated environmental impact of manufacturing new products. Investing in high-quality stainless steel floor drain covers can result in long-term cost savings and environmental benefits.

Future Trends in Stainless Steel Floor Drain Covers

The field of material science is constantly evolving, and new developments in stainless steel technology are likely to impact the production of floor drain covers.

Advanced Alloys

Research into advanced alloys aims to improve the properties of stainless steel, making it even more resistant to corrosion and wear. These new materials could offer enhanced performance for floor drain covers, especially in demanding environments.

Smart Manufacturing

The integration of smart technology into manufacturing processes is set to revolutionize the production of stainless steel floor drain covers. Real-time monitoring and automation can improve efficiency, reduce waste, and ensure consistent quality. Smart manufacturing techniques can also enable more complex and customized designs.

Eco-Friendly Innovations

As sustainability becomes a priority, manufacturers are exploring eco-friendly innovations in stainless steel production. These include energy-efficient manufacturing processes, the use of renewable energy sources, and the development of coatings and treatments that further enhance the material’s durability and environmental performance.

FAQs

What are the main benefits of using stainless steel for floor drain covers?

Stainless steel offers excellent corrosion resistance, durability, and hygiene, making it ideal for floor drain covers. It is easy to clean and maintain, ensuring long-term performance in various environments.

How does CNC perforation improve the production of floor drain covers?

CNC perforation provides high precision and consistency, allowing for complex and intricate designs. This technique reduces material waste and ensures consistent quality, making it an efficient and cost-effective production method.

Why is corrosion resistance important for floor drain covers?

Corrosion resistance is crucial for floor drain covers because they are often exposed to water, chemicals, and other corrosive substances. Stainless steel’s ability to resist corrosion ensures that the covers remain functional and aesthetically pleasing over time.

Can stainless steel floor drain covers be customized?

Yes, stainless steel floor drain covers can be customized to meet specific design and functional requirements. CNC perforation and laser cutting techniques enable the production of bespoke designs and patterns, ensuring a perfect fit and optimal performance.

What surface treatments are available for stainless steel floor drain covers?

Common surface treatments for stainless steel floor drain covers include passivation, electropolishing, and powder coating. These treatments enhance corrosion resistance, improve hygiene, and provide a decorative finish.

Is stainless steel an environmentally friendly material?

Stainless steel is environmentally friendly due to its recyclability and longevity. It can be recycled without losing its properties, reducing the need for virgin materials. Its durability also means that products have a long lifespan, reducing the environmental impact of frequent replacements.

Customize Your Floor Drain Cover

The integration of material science and advanced manufacturing techniques in producing stainless steel floor drain covers leads to high-quality, durable, and visually appealing products. Combining the characteristics of different grades of stainless steel, using CNC perforation and laser cutting, our factory can create high-quality floor drain covers for you that are suitable for different environments. As technology and sustainability practices advance, the future of stainless steel floor drain covers looks bright, with innovations poised to enhance both performance and environmental impact.