This article explores the use of CNC perforated sheets in manufacturing floor drain covers. It highlights the precision, efficiency, and customization offered by CNC technology, making it ideal for producing durable and aesthetically pleasing drain covers. The article covers the benefits, material options, design flexibility, environmental and economic impacts, and technological advancements in CNC perforation. It also discusses the importance of proper installation and maintenance to maximize the benefits of CNC perforated floor drain covers. Future trends in CNC technology and material innovation are also examined.

Introduction to CNC Perforated Sheets

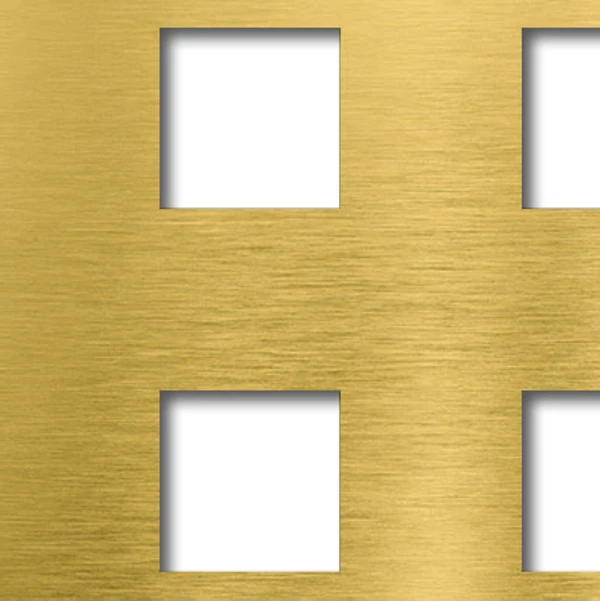

CNC perforated sheets are created using computer numerical control (CNC) technology. This method ensures precision, speed, and efficiency, surpassing traditional manual punching techniques. CNC technology accommodates various materials, including stainless steel, galvanized steel, aluminum, copper, and brass. These materials are shaped into simple geometric forms or intricate designs, allowing for extensive customization and high-quality output. These sheets are widely used in numerous applications due to their reliability and adaptability.

Benefits of Using CNC Perforated Sheets for Floor Drain Covers

CNC perforated sheets offer several advantages, making them ideal for manufacturing floor drain covers. Their precision ensures high-quality production, resulting in covers that fit perfectly and function efficiently. CNC technology enables the creation of complex and consistent designs that manual methods cannot achieve. The process is fast and cost-effective, reducing production time and costs. Additionally, CNC perforated sheets minimize material waste through exact measurements and cutting paths, further enhancing their economic value.

Material Options for Floor Drain Covers

Manufacturers use various materials to produce floor drain covers with CNC perforated sheets. Each material has unique properties that suit different applications:

- Stainless Steel: Known for its strength, corrosion resistance, and aesthetic appeal. Ideal for environments exposed to moisture and harsh conditions.

- Galvanized Steel: Durable and cost-effective. Suitable for industrial and high-traffic areas.

- Aluminum: Lightweight, corrosion-resistant, and easy to work with. Perfect for architectural and decorative applications.

- Copper and Brass: Chosen for their distinctive appearance and excellent conductivity. Often used in specialized and aesthetic-focused applications.

Design Flexibility and Customization

CNC technology offers significant design flexibility, enabling the customization of floor drain covers to meet specific needs. Clients can specify shapes, sizes, and patterns to match their requirements. CNC machines can produce intricate and complex designs, providing high design flexibility. This customization is beneficial for architects and designers looking to create unique and functional spaces. It also ensures that the covers fit perfectly into larger systems, optimizing performance and integration.

Environmental and Economic Benefits

CNC perforated sheets contribute positively to environmental sustainability. The precision of CNC machines reduces material waste, conserving resources. Additionally, the ability to use recycled materials in production aligns with eco-friendly practices. Economically, CNC perforated sheets offer cost savings through efficient production processes and reduced material wastage. Their durability and low maintenance requirements further enhance their cost-effectiveness, making them an attractive option for businesses looking to balance environmental responsibility and economic efficiency.

Installation and Maintenance of Floor Drain Covers

Proper installation and maintenance are essential for maximizing the benefits of CNC perforated floor drain covers. Professional installation ensures stability and durability. Maintenance involves regular cleaning to prevent the buildup of dirt and debris, which can affect functionality and appearance. Depending on the material, specific cleaning methods may be required to avoid damage. For example, stainless steel may require a mild detergent, while aluminum might need a non-abrasive cleaner. Routine inspections can help identify and address issues early, extending the lifespan of the covers.

Technological Advancements and Future Trends

Technological advancements continue to enhance the capabilities of CNC perforation. Innovations in CNC software improve design capabilities, allowing for more complex and precise patterns. Advances in machine technology enhance production speed and efficiency. Developments in material science expand the range of materials that can be effectively perforated, providing more options for various applications. These advancements ensure that CNC perforated sheets remain at the forefront of modern manufacturing and design.

The future of CNC perforated sheets and floor drain covers looks promising with ongoing trends and innovations. Increased automation in CNC machining is expected to further enhance production efficiency and precision. The integration of smart technology in manufacturing processes will enable real-time monitoring and adjustments, ensuring optimal performance. Sustainability will continue to drive material choices, with a focus on recycled and eco-friendly options. Design trends will likely see more intricate and personalized patterns, reflecting the growing demand for unique and customized solutions.

Conclusion

CNC perforated sheets and floor drain covers provide versatile and efficient solutions for various applications. Their precision, speed, and customization options make them superior to traditional manual methods. Available in multiple materials, these products meet diverse industry needs. Whether used for architectural projects, industrial applications, or specialized designs, CNC perforated sheets and floor drain covers offer high quality, functionality, and aesthetic appeal. Embracing CNC technology in the production of perforated sheets and floor drain covers provides significant advantages in today’s competitive market. The future promises continued innovation and growth, driven by advancements in technology and design.