To choose the best custom floor trap covers for commercial and industrial use, consider the material (stainless steel, cast iron, or plastic), load capacity, environmental exposure, and specific customization needs. For optimal performance and service life, proper installation and regular maintenance are as important as “How to Choose”.

Introduction and Application Scenarios

Floor trap covers are widely used in a variety of commercial and industrial settings. They ensure proper drainage and hygiene, and protect systems from damage.

Commercial Kitchens

In commercial kitchens, these covers prevent food debris and grease from clogging the drains, ensuring smooth operations and hygiene.

Industrial Environments

In industrial environments like factories and warehouses, floor trap covers handle significant volumes of water and heavy loads, protecting the drainage system from damage caused by machinery and high foot traffic.

Hospitals and Laboratories

Hospitals and laboratories rely on floor trap covers to maintain sterile conditions by preventing contaminants from entering the drainage system.

Choose the right custom floor trap cover to meet the specific needs of these different environments.

At FILTERMFRS™, we understand the importance of high-quality, durable floor trap covers and offer a wide range of customizable and wholesale options to meet specific needs. In this comprehensive guide, we discuss the use cases for floor trap covers, product knowledge, how to choose a custom floor trap cover, and advice on subsequent maintenance and repairs.

Understanding Floor Trap Covers

Floor trap covers protect drainage systems. They are common in commercial and industrial settings. These covers sit over drain openings. They prevent solid waste from entering. Water passes through. This maintains system efficiency. It prevents blockages. Blockages lead to costly repairs and downtime.

Common Materials:

- Stainless Steel: Known for its durability and resistance to corrosion, making it ideal for wet environments.

- Cast Iron: Extremely robust and can handle heavy loads, suitable for industrial applications.

- Plastic: Lightweight and cost-effective, though less durable than metal options.

In hygienic settings like kitchens and hospitals, stainless steel (specifically grades 304 and 316) is favored for its rust resistance and effortless upkeep. Conversely, cast iron is selected for its exceptional durability and resilience under heavy foot traffic, making it ideal for industrial spaces such as warehouses and factories.

Specifications and Types of Floor Trap Covers

Specifications of Floor Trap Covers

When selecting a floor trap cover, it’s important to consider the specifications to ensure it meets your needs. These specifications include size, material, and finish.

| Specification | Options | Applications |

|---|---|---|

| Size | 92×92 mm, 100×100 mm, 110×110 mm, 125×125 mm, 135×135 mm, 150×150 mm, 180×180 mm | Small to large drainage openings,Circle, square, triangle, and irregular shape. |

| Material | SS 304, SS 316, Brass | Corrosion resistance, strength, aesthetics |

| Finish | Mirror, Brushed, Matte | Matching interior design, ease of cleaning |

Types of Floor Trap Covers

Different types of floor trap covers are available to suit various drainage needs:

- Standard Flow Drains: These are suitable for general drainage applications. They handle typical water flow rates and are commonly used in residential and light commercial settings.

- High Flow Drains: Designed for areas with higher water usage, such as commercial kitchens or showers. These covers can handle larger volumes of water and prevent overflow.

- Tile-In Covers: These are integrated into the floor tiles, providing a seamless appearance. They are popular in bathrooms and kitchens where aesthetics are important.

- Magnetic Covers: Easy to install and remove, these covers use magnets to stay in place. They are ideal for areas that require frequent access to the drain for cleaning or maintenance.

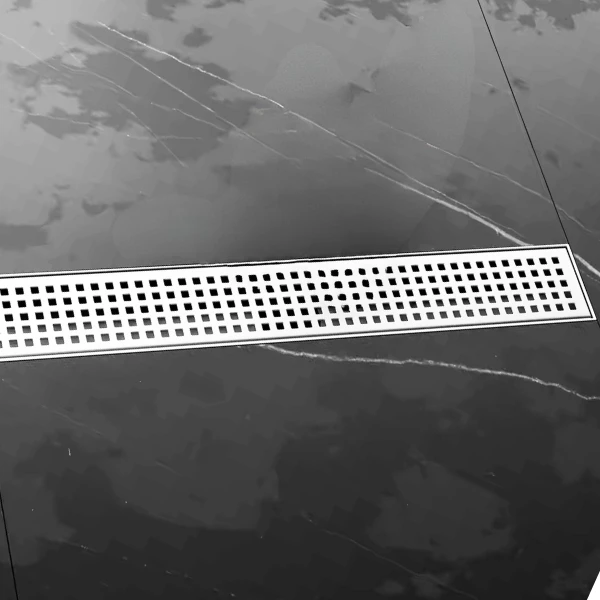

- Linear Covers: Used in showers and other elongated drainage areas. They provide effective water drainage over a larger area and are often used in modern bathroom designs.

Material Selection for Floor Trap Covers

Choosing the right material for your floor trap cover ensures durability, hygiene, and performance. The following are several common materials:

Stainless Steel 304

Stainless steel 304 is known for its corrosion resistance and durability. It’s suitable for environments exposed to water and chemicals, like kitchens and laboratories. Its easy-to-clean surface makes it ideal for maintaining hygiene in commercial kitchens.

Stainless Steel 316

Stainless steel 316 offers superior corrosion resistance compared to 304. It’s ideal for harsher environments like marine or industrial settings. It resists chlorides and acids, making it a better choice for chemical plants or swimming pools.

Cast Iron

Cast iron is extremely durable and capable of handling heavy loads. It is suitable for industrial settings where heavy machinery and high foot traffic are common. It withstands harsh conditions and is less likely to break under pressure.

Plastic

Plastic floor trap covers are lightweight and cost-effective. They are suitable for less demanding environments. While not as durable as metal options, they offer an economical solution for areas with lower foot traffic and minimal exposure to harsh chemicals.

The appropriate material depends on your environment. A commercial kitchen benefits from the hygienic properties of stainless steel. An industrial warehouse requires the strength and durability of cast iron.

Production and Customization of Floor Trap Covers

Production Process of Custom Floor Trap Covers

The production of floor trap covers involves several meticulous steps to ensure quality and durability. The process typically includes:

- Casting or Cutting:This is the first step in forming the basic shape of your floor trap cover. Outdoor drain covers are usually made of cast iron, which is thick and heavy and can withstand heavy loads and harsh conditions. Indoor floor drain covers are usually obtained by laser cutting 304 or 316 stainless steel plates about 1mm thick.

- Molding: In this stage, finer details such as patterns and logos can be added to the cover. This is particularly important for custom orders where specific designs are requested by clients. Molding allows for high precision and consistency in the design elements.

- Finishing: Once the basic shape and details are in place, the cover undergoes finishing processes. This can include polishing, brushing, or applying a matte finish, depending on the client’s preferences. Finishing not only enhances the aesthetic appeal but also improves the cover’s resistance to corrosion and wear.

- Quality Control: Each floor trap cover is inspected for defects and tested to ensure it meets the required standards. This step is crucial to ensure that the product is safe, reliable, and durable. Quality control measures might include pressure testing, load testing, and visual inspections.

Customization Options for Floor Trap Covers

Customization is a significant advantage when choosing floor trap covers. Custom options allow businesses to tailor the covers to their specific needs, enhancing both functionality and aesthetics.

- Custom Shapes and Sizes: Floor trap covers can be manufactured in various shapes and sizes to fit unique drainage systems. This flexibility ensures that the covers fit perfectly, preventing leaks and enhancing efficiency.

- Design Patterns and Finishes: Custom design patterns can include logos, geometric shapes, or decorative elements that complement the surrounding decor. Different finishes such as mirror, brushed, and matte can be selected to match the aesthetic of the installation environment.

- Material Customization: Depending on the application, clients can choose from different materials like stainless steel 304, stainless steel 316, cast iron, or even specialized plastics. Each material offers distinct advantages and can be selected based on the specific requirements of the environment where the cover will be used.

Examples of Custom Orders:

- Logos and Branding: Businesses can incorporate their logos into the floor trap covers, providing a unique branding opportunity. This is particularly popular in commercial spaces where brand visibility is important.

- Specific Drainage Patterns: Custom drainage patterns can be designed to handle specific water flow rates and volumes. This is useful in environments with unique drainage needs, such as laboratories or commercial kitchens.

Installation Guidelines

Preparation for Installing Floor Trap Covers

Proper installation of floor trap covers begins with thorough preparation. This step ensures that the cover fits perfectly and functions efficiently.

- Clean the Drain Area: Start by cleaning the drain opening and surrounding area. Remove any debris, old sealant, or dirt that could interfere with the installation. This ensures a clean surface for the new cover to sit on and prevents gaps that could cause leaks.

- Accurate Measurements: Measure the drain opening accurately. For round drains, measure the diameter; for square or rectangular drains, measure the length and width. Accurate measurements ensure that the cover fits snugly, preventing water from bypassing the cover and entering the drain improperly.

- Check for Obstructions: Ensure there are no obstructions around the drain opening that could prevent the cover from sitting flush with the floor. This includes checking for uneven surfaces or protrusions that might need to be leveled or removed.

Installation Steps for Custom Floor Trap Covers

- Position the Cover: Place the custom floor trap cover over the drain opening. Ensure it is properly aligned and sits flush with the surrounding floor. This is crucial for preventing water from pooling around the cover and ensuring efficient drainage.

- Secure the Cover: Depending on the design, secure the cover using appropriate methods such as screws, bolts, or adhesives. If screws are used, ensure they are evenly spaced and tightened to prevent any movement. For adhesive installations, use a sealant that is compatible with the cover material and the floor surface.

- Seal the Edges: Apply a bead of silicone sealant around the edges of the cover to ensure a watertight fit. This step is particularly important in wet environments, such as bathrooms and kitchens, to prevent water from seeping under the cover.

- Test the Installation: Once the cover is secured, pour water over it to test the installation. Check for any leaks or areas where water is not draining properly. Make adjustments as needed to ensure the cover is functioning correctly.

Professional Installation of Custom Floor Trap Covers

While DIY installation is possible, hiring professionals can ensure that the job is done correctly and efficiently. Professional installers have the experience and tools necessary to handle complex installations and can troubleshoot any issues that arise during the process. This can save time and prevent potential problems that could lead to costly repairs in the future.

Benefits of Professional Installation:

- Expertise: Professionals have the knowledge to install covers correctly, ensuring they meet industry standards.

- Efficiency: Professional installers can complete the job quickly and with minimal disruption to your operations.

- Warranty: Many professional services offer warranties on their work, providing peace of mind that any issues will be addressed promptly.

Maintenance and Longevity of Floor Trap Covers

Regular Maintenance of Floor Trap Covers

Maintain your floor trap cover regularly to ensure its longevity and functionality. Proper maintenance practices prevent the buildup of debris, reduce wear and tear, and maintain hygiene standards, especially in commercial and industrial settings.

- Cleaning: Regular cleaning is crucial to remove debris, dirt, and residues that can accumulate over time. Use mild soap and water for routine cleaning. Avoid harsh chemicals that could damage the surface of the cover, particularly for stainless steel and plastic materials. For tougher stains, a soft-bristle brush can help scrub the surface without scratching it.

- Inspections: Conduct periodic inspections to check for signs of wear and tear. Look for any cracks, rust spots, or loosening of the cover. Addressing these issues early can prevent more significant problems and extend the cover’s lifespan.

- Lubrication: For covers with moving parts, such as those with magnetic closures, ensure they are adequately lubricated to maintain smooth operation. Use appropriate lubricants that do not corrode the material.

- Re-sealing: Over time, the sealant around the edges of the cover may degrade. Inspect the sealant periodically and reapply as necessary to maintain a watertight fit. This is particularly important in environments exposed to constant moisture, such as kitchens and bathrooms.

Durability of Custom Drain Covers

The durability of a floor trap cover largely depends on the material used and the environment in which it is installed. Different materials offer varying degrees of durability and require different maintenance routines.

- Stainless Steel 304 and 316: These materials are highly durable and resistant to corrosion, making them ideal for wet and chemically harsh environments. With proper maintenance, stainless steel covers can last for decades. Regular cleaning and inspections are usually sufficient to keep them in good condition.

- Cast Iron: Known for its strength and durability, cast iron can handle heavy loads and harsh industrial conditions. However, it is prone to rust if not properly maintained. Regular cleaning, drying, and application of anti-rust coatings can significantly extend the lifespan of cast iron covers.

- Plastic: While plastic covers are less durable than metal options, they can still provide long service life if used in appropriate environments and maintained well. Avoid exposing plastic covers to excessive weight and harsh chemicals that could cause cracking or degradation.

Recommendations for Specific Environments

Different environments have unique requirements that influence the choice of material and maintenance practices for floor trap covers.

- Commercial Kitchens: In a high-use environment like a commercial kitchen, stainless steel 304 covers are recommended due to their corrosion resistance and ease of cleaning. Regular inspections and cleaning routines are essential to prevent food particles and grease buildup.

- Industrial Warehouses: For heavy-duty industrial settings, cast iron covers are ideal. Their ability to withstand heavy loads and harsh conditions makes them suitable for areas with forklifts and other heavy machinery. Regular application of anti-rust treatments and frequent inspections can help maintain their durability.

- Chemical Plants: In environments exposed to corrosive chemicals, stainless steel 316 is preferable due to its superior resistance to chlorides and acids. Clean regularly using an appropriate cleaning agent that does not react with the material.

Environmental Considerations for Floor Trap Covers

Sustainability of Custom Drain Covers

Stainless steel, particularly grades 304 and 316, is widely used in the production of floor trap covers due to its durability and resistance to corrosion. However, the production of stainless steel has significant environmental implications that need to be considered.

- Energy Consumption: The production of stainless steel is highly energy-intensive. It involves processes such as melting and refining iron ore, which require large amounts of energy, primarily from fossil fuels. This leads to substantial greenhouse gas emissions. The stainless steel industry is responsible for about 230 million tons of carbon dioxide emissions annually, equivalent to the emissions from over 50 million cars.

- Resource Use: Stainless steel production relies heavily on raw materials like iron ore, chromium, and nickel. The extraction and transportation of these raw materials contribute to environmental degradation, including deforestation and habitat destruction. Additionally, the mining processes often result in significant water and soil pollution due to the release of hazardous chemicals and metals.

- Waste Generation: During the production of stainless steel, by-products such as slag, dust, and wastewater are generated. These waste materials contain hazardous substances like lead, cadmium, mercury, and chromium, which can contaminate the environment if not managed properly. Proper handling and disposal of these by-products are crucial to minimize their impact on ecosystems and human health.

Mitigation Measures

To reduce the environmental impact of stainless steel production, several measures can be implemented:

- Energy Efficiency: Improving the efficiency of the steelmaking process can significantly reduce energy consumption. This can be achieved through technological advancements and the adoption of more energy-efficient equipment.

- Alternative Energy Sources: Using renewable energy sources such as solar, wind, or hydroelectric power can help lower the carbon footprint of stainless steel production. This transition not only reduces greenhouse gas emissions but also lessens the industry’s reliance on fossil fuels.

- Recycling and Reuse: Promoting the recycling and reuse of stainless steel products can reduce the need for virgin raw materials and decrease waste generation. Stainless steel is fully recyclable, and recycling processes consume less energy compared to the production of new steel. Encouraging a circular economy model where stainless steel is continuously recycled can help mitigate environmental impacts.

How to Choose the Best Custom Floor Trap Covers

Selecting the right custom floor trap covers involves several critical factors that ensure both functionality and durability. Here are some guidelines to help you make the best choice for your commercial or industrial setting.

Assessing Your Needs for Custom Floor Trap Covers

The first step in choosing the right floor trap cover is to evaluate the specific needs of your environment. Consider the following aspects:

- Load Capacity: Determine the amount of weight the cover needs to support. High-traffic areas and places with heavy machinery require covers that can withstand significant loads. For instance, cast iron covers are suitable for industrial settings due to their strength and durability.

- Environmental Exposure: Identify the type of environment where the cover will be used. Areas exposed to chemicals, moisture, and extreme temperatures may require materials like stainless steel 316, which offers superior corrosion resistance.

- Hygiene Requirements: For environments where hygiene is critical, such as commercial kitchens and healthcare facilities, stainless steel 304 is ideal due to its ease of cleaning and resistance to bacterial growth.

Comparing Materials for Floor Trap Covers

Choosing the right material is crucial for ensuring the longevity and performance of the floor trap cover. Here’s a comparison of common materials:

| Material | Benefits | Suitable Environments |

|---|---|---|

| Stainless Steel 304 | Corrosion resistance, hygienic, durable | Commercial kitchens, hospitals, laboratories |

| Stainless Steel 316 | Superior corrosion resistance, durable | Chemical plants, marine environments |

| Cast Iron | High load capacity, very durable | Industrial warehouses, heavy machinery areas |

| Plastic | Lightweight, cost-effective | Light-duty environments, non-corrosive areas |

Custom Design Options for Floor Trap Covers

Customization allows you to tailor floor trap covers to your specific needs, enhancing both functionality and aesthetics. Consider the following options:

- Shapes and Sizes: Custom covers can be made to fit unique drain openings, ensuring a perfect fit and efficient drainage.

- Design Patterns: Incorporate logos, geometric shapes, or other decorative elements to match the aesthetic of your space. Custom patterns can also enhance the cover’s functionality by improving water flow and debris capture.

- Finishes: Choose from various finishes such as brushed, polished, or matte to match your design preferences and the specific requirements of your environment.

Consulting with Experts on Custom Floor Trap Covers

To ensure you select the best floor trap cover, consulting with experts can provide valuable insights and recommendations tailored to your needs. Companies like FILTERMFRS™ offer professional advice and can help you design custom covers that meet all your specifications.

Benefits of Consulting Experts:

- Tailored Solutions: Experts can assess your specific needs and recommend the best materials, designs, and installation methods.

- Quality Assurance: Professional advice ensures that the covers you select meet industry standards for safety and performance.

- Installation Services: Many suppliers offer installation services, ensuring the covers are fitted correctly and function as intended.

Conclusion

Selecting the right custom floor trap covers for commercial and industrial use involves several important considerations, from understanding the types and materials to assessing specific needs and ensuring proper installation. By focusing on these key factors, you can ensure that the floor trap covers you choose are durable, efficient, and aesthetically pleasing.

Key Takeaways:

- Material Selection: Choose materials based on the environment and specific needs. Stainless steel 304 is excellent for environments requiring high hygiene, while stainless steel 316 offers superior corrosion resistance for harsher conditions. Cast iron is ideal for heavy-duty industrial settings, and plastic can be a cost-effective solution for light-duty applications.

- Customization: Take advantage of customization options to ensure the covers fit perfectly and meet specific functional and aesthetic requirements. Custom shapes, sizes, patterns, and finishes can enhance the performance and appearance of the floor trap covers.

- Installation: Proper installation is crucial for ensuring the covers function correctly. Consider professional installation services to ensure a watertight fit and optimal performance.

- Maintenance: Regular cleaning and inspections are essential to maintain the functionality and longevity of the covers. Each material has specific maintenance needs that should be adhered to for best results.

- Environmental Impact: Consider the sustainability of the materials used. Stainless steel, being fully recyclable, is an environmentally friendly option that supports waste reduction and longevity.

By carefully considering these aspects and consulting with experts like those at FILTERMFRS™, you can select custom floor trap covers that meet all your commercial or industrial requirements effectively. Ensuring a proper fit, durability, and ease of maintenance will lead to better performance and reduced long-term costs.

FAQs

Choosing the best custom floor trap covers can be complex, and potential buyers often have numerous questions. Here are some frequently asked questions along with their answers to help guide your decision-making process.

How often should floor trap covers be cleaned?

Clean regularly to maintain the functionality and hygiene of your floor trap cover. The frequency depends on the environment:

- Commercial Kitchens: Clean daily or after every use to prevent grease and food debris buildup.

- Industrial Settings: Weekly cleaning is recommended to remove dust, dirt, and chemical residues.

- Healthcare Facilities: Daily cleaning with disinfectants to maintain high hygiene standards.

What material is best for industrial environments?

For industrial settings, the best materials are typically those that can withstand heavy loads and harsh conditions:

- Cast Iron: Known for its durability and strength, making it suitable for areas with heavy machinery and high foot traffic.

- Stainless Steel 316: Offers superior resistance to corrosion, especially in environments exposed to chemicals and moisture.

Can custom drain covers be designed to match specific aesthetics?

Yes, custom drain covers can be designed to meet specific aesthetic requirements. This includes:

- Custom Shapes and Sizes: Ensuring a perfect fit for unique drainage systems.

- Design Patterns: Incorporating logos, geometric patterns, or other decorative elements.

- Finishes: Choosing from brushed, polished, or matte finishes to match the surrounding decor.

What should be considered for high-traffic areas?

In high-traffic areas, the following factors should be considered to ensure the floor trap covers are durable and effective:

- Load-Bearing Capacity: Ensure the cover can support the expected weight, whether it’s pedestrian traffic or heavy machinery.

- Material: Opt for robust materials like cast iron or stainless steel to handle the wear and tear.

- Maintenance: Perform regular maintenance to keep the cover in good condition and prevent potential hazards.

How do I ensure a proper fit for custom covers?

Ensuring a proper fit for custom floor trap covers involves several steps:

- Accurate Measurements: Measure the dimensions of the drain opening precisely. This includes the diameter for round drains or the length and width for square or rectangular drains.

- Professional Consultation: Working with experts can help in designing covers that meet specific requirements and ensure a perfect fit.

- Installation: Hiring professionals to install the covers can ensure they are secured correctly and function as intended.

Additional FAQs:

Can custom drain covers be made from eco-friendly materials?

Yes, stainless steel is fully recyclable and can be considered an eco-friendly option.

What are the benefits of using magnetic covers?

Magnetic covers offer easy installation and removal, making them ideal for areas that require frequent access to the drain for cleaning or maintenance.