Learn about calculating perforated metal sheet open area through this blog. Understand the importance, uses, and detailed calculation methods to optimize your designs. Start customizing your perforated sheets from FILTERMFRS™.

What is Perforated Metal Sheet Open Area

The open area of a perforated metal sheet is the percentage of the sheet’s surface that consists of holes. This percentage indicates how much of the sheet is open space, affecting airflow, light passage, and material strength. It ensures that the perforated sheet meets the necessary functional and structural requirements for various uses.

What is the Use of Perforated Metal Sheet Open Area and How to Use It

The calculation of open area is essential for applications requiring specific ventilation, filtration, or aesthetic properties. In architectural design, it provides a balance between light penetration and privacy, enhancing aesthetic appeal. Industrial applications use it for effective filtration and separation, controlling airflow in HVAC systems, and sound absorption in acoustic panels. By understanding the open area percentage, designers and engineers can select the appropriate perforated sheet to meet specific project needs, ensuring optimal performance and durability.

How to Calculate Perforated Metal Sheet Open Area

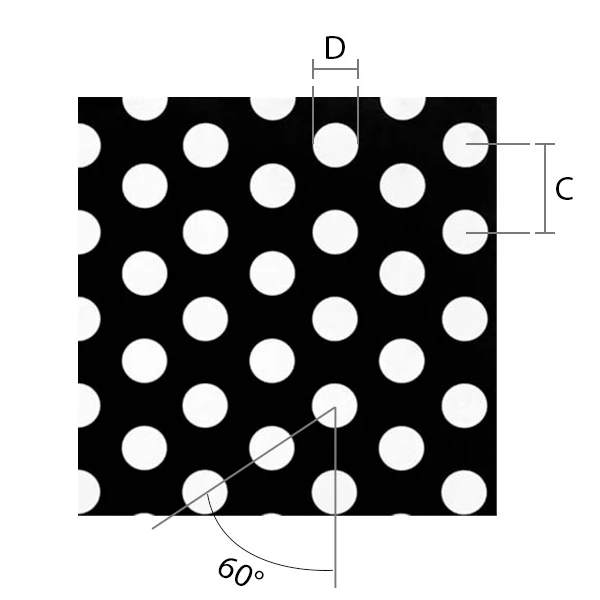

Round 60 Degree Staggered Centers

The open area for round holes in a 60-degree staggered pattern is calculated using:

Open Area Percentage = (D² x 90.69 / C²) %

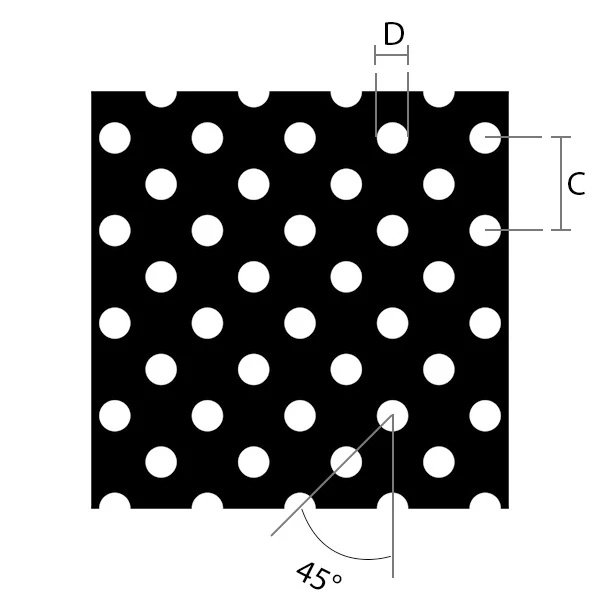

Round 45 Degree Staggered Centers

For round holes in a 45-degree staggered pattern, the formula is:

Open Area Percentage = (D² x 78.54 / C²) %

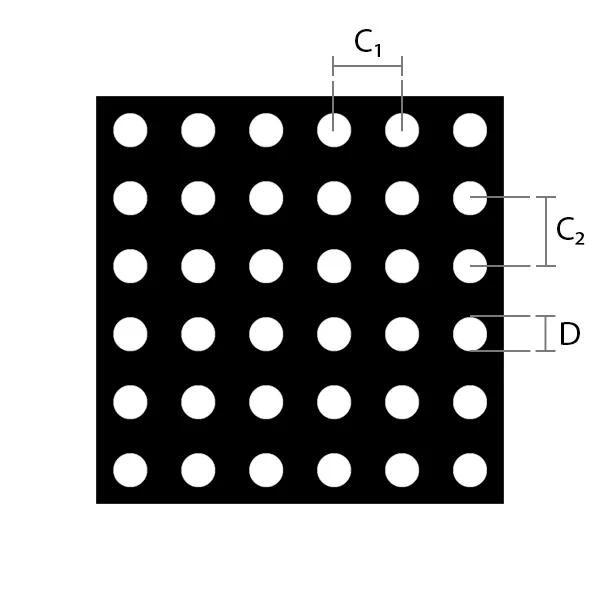

Round Straight Centers

The calculation for round holes in straight centers is:

Open Area Percentage = (D² x 78.54 / C₁C₂) %

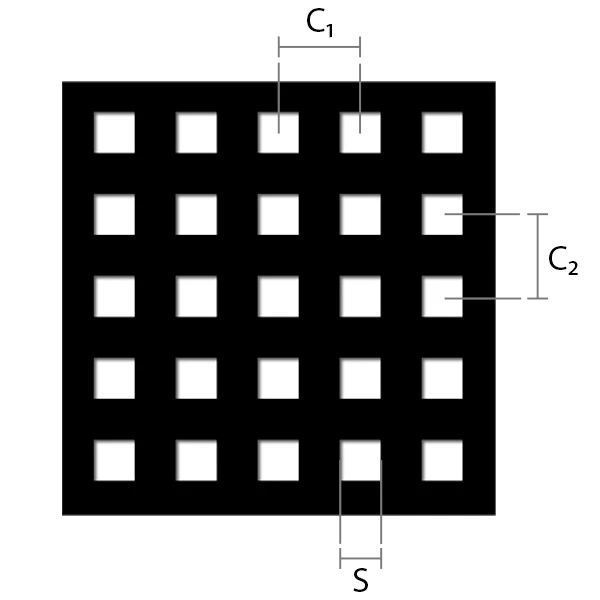

Square Straight Centers

For square holes in straight centers:

Open Area Percentage = (S²x 100 / C₁C₂)%

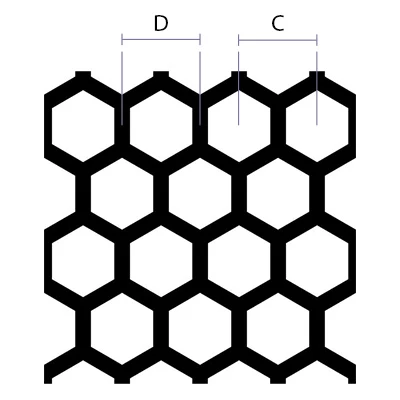

Hex 60 Degree Staggered Centers

For hexagonal holes in a 60-degree staggered pattern:

Open Area Percentage = (100 x D² / C²) %

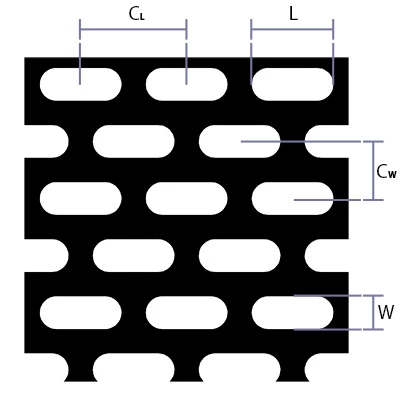

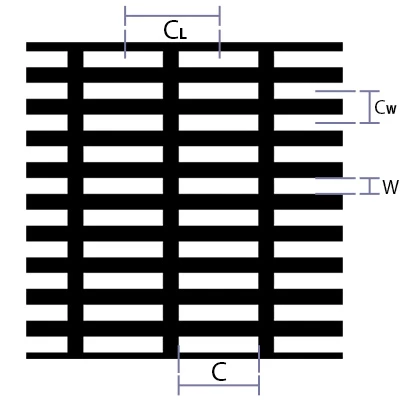

Slotted Round End Side Staggered Centers

For slotted holes with round ends in a side-staggered pattern:

Open Area Percentage = ((W(L – .215W) / CL x Cw) x 100) %

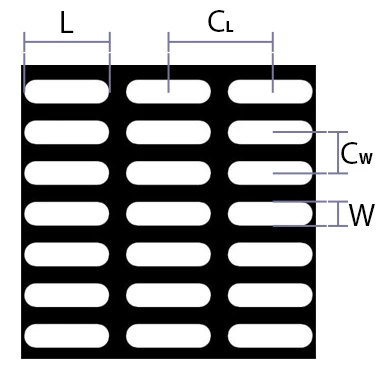

Slotted Round End Straight Centers

For slotted holes with round ends in straight centers:

Open Area Percentage = ((W(L – .215W) / CL x Cw) x 100) %

Slotted Square End Staggered Centers

For slotted holes with square ends in staggered centers:

Open Area Percentage = ((L x W / CL x Cw) x 100) %

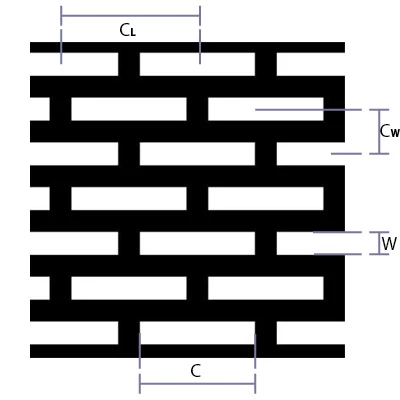

Slotted Square End Straight Centers

For slotted holes with square ends in straight centers:

Open Area Percentage = ((L x W / CL x Cw) x 100) %

Specific Applications of Perforated Metal Sheet Open Area

Perforated metal sheets are used in various applications:

- Architecture: Enhances building aesthetics, provides natural lighting, and maintains privacy.

- Industrial Filtration: Essential in separating particles and ensuring clean airflow.

- HVAC Systems: Improves ventilation and air distribution.

- Acoustic Panels: Manages sound absorption and reduces noise levels.

- Food Processing: Filters and screens for food products, ensuring hygiene and safety.

Customize Your Perforated Sheets

Understanding and calculating the open area of perforated metal sheets is crucial for optimizing their use in diverse applications. Whether for architectural aesthetics, industrial filtration, or acoustic management, the right open area ensures the material meets functional and structural needs. By applying the appropriate formulas and considering specific project requirements, designers and engineers can achieve the desired balance of efficiency, strength, and visual appeal. Customize your perforated sheets from our factory to meet your exact specifications and enhance the performance of your projects.