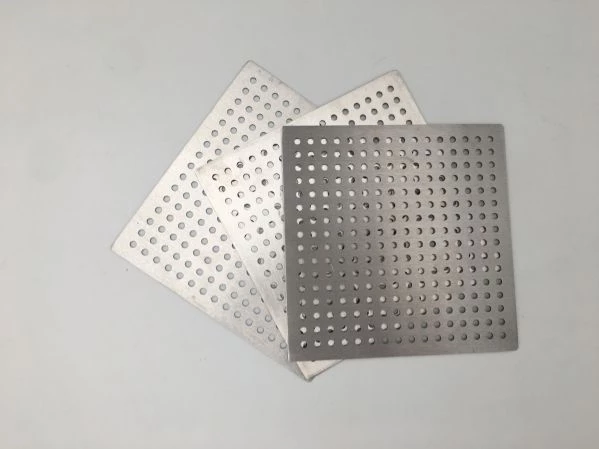

A safety filter, also known as a security filter or guard filter, is a crucial component used in various industries to ensure the purity and safety of fluids and gases. These filters are designed to protect systems and end-users by removing harmful contaminants, such as particles, bacteria, and other impurities. By implementing a high-security filter, industries can maintain the integrity of their processes and protect both machinery and human health. Safety filters are used in various applications, including water treatment, pharmaceuticals, food and beverage processing, and industrial manufacturing.

What is Safety Filter

The history of the safety filter dates back to ancient civilizations, where rudimentary filtration methods were used to purify water. Over time, the development of more sophisticated filtration systems evolved alongside advancements in technology. In the early 20th century, the industrial revolution brought about significant innovations in filtration technology, leading to the creation of the modern safety filter. Initially used primarily in water treatment, the application of safety filters expanded into other industries as the need for purity and safety became paramount. The introduction of stainless steel security filters marked a significant milestone, offering enhanced durability and resistance to corrosion.

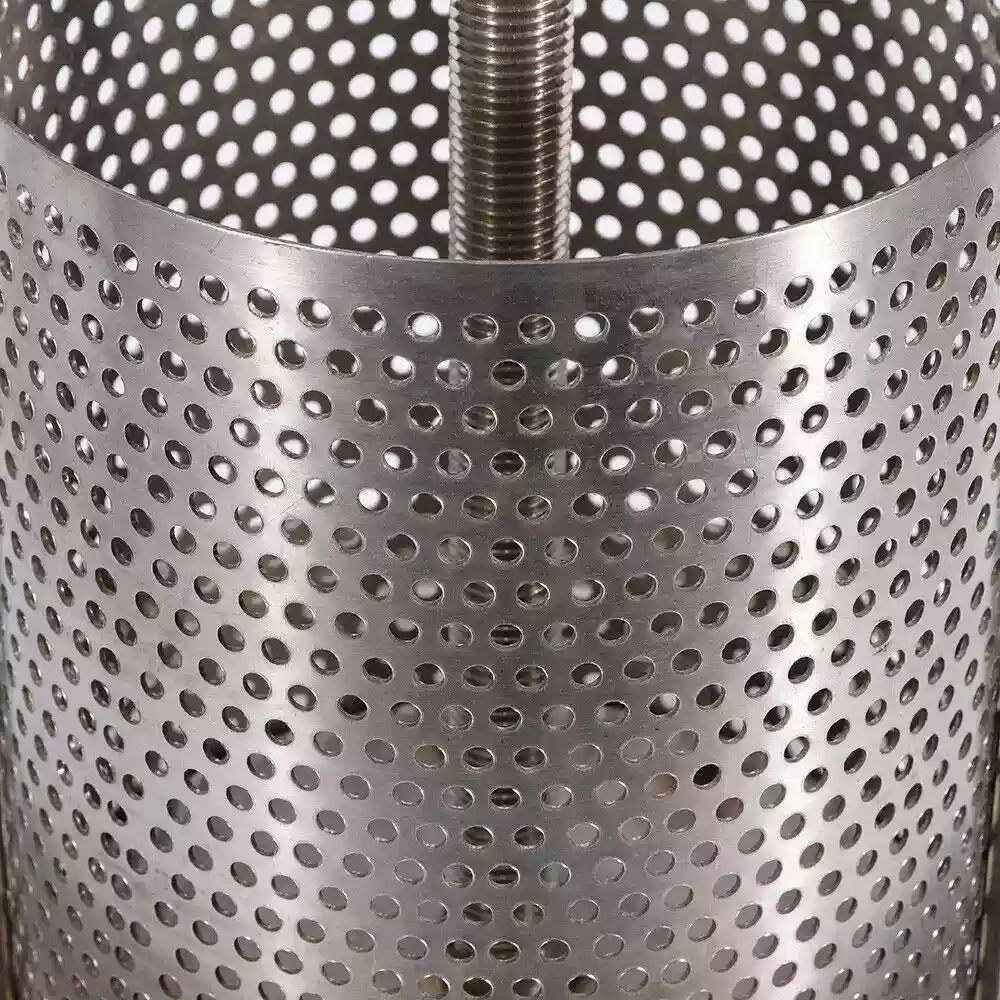

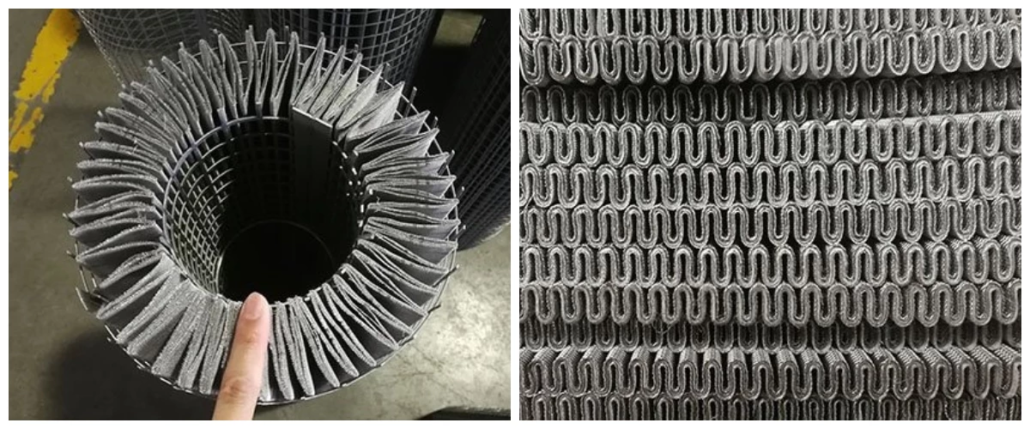

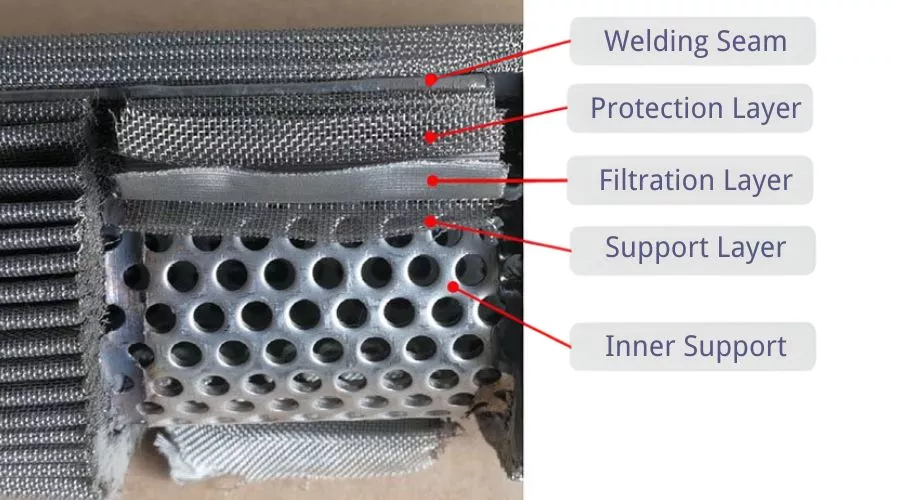

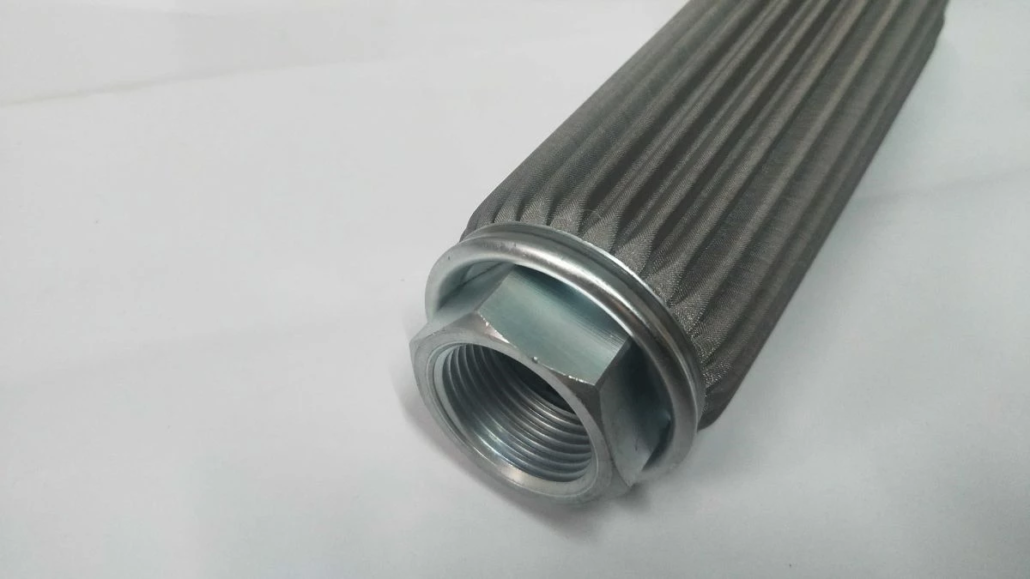

The structure of Safety Filter

The structure of a safety filter is meticulously designed to achieve optimal filtration performance. A typical safety filter consists of several key components:

- Filter Housing: The outer casing, often made from materials like stainless steel, provides structural support and protects the internal components.

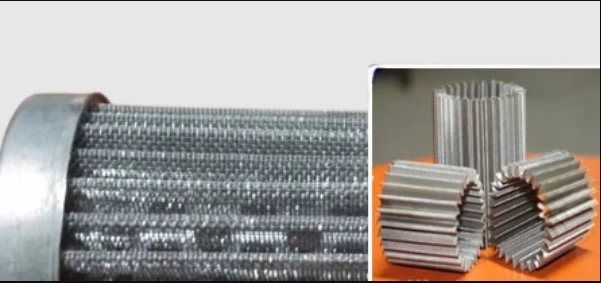

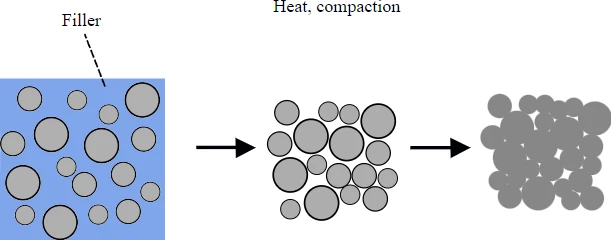

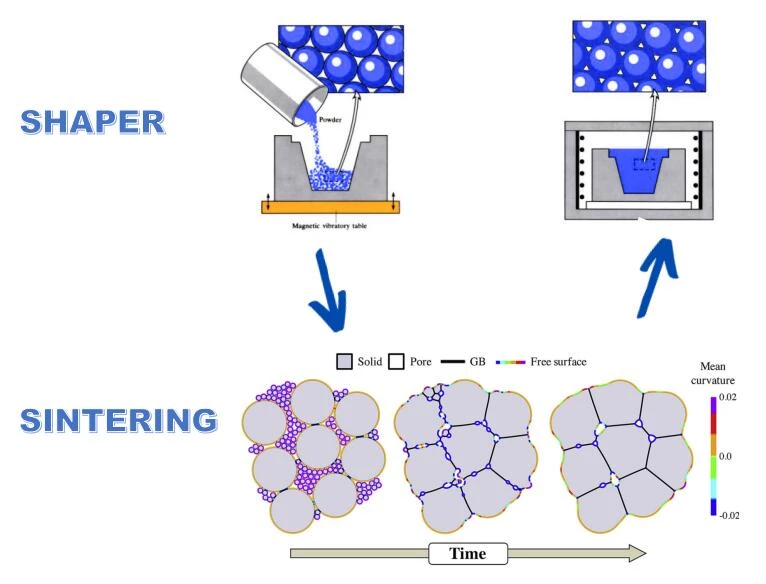

- Filter Media: This is the core component responsible for trapping contaminants. The filter media can be made from various materials, including mesh, membranes, or sintered metal, depending on the application.

- Pre-filter: An initial layer that captures larger particles, prolonging the life of the primary filter media.

- Seals and Gaskets: These components ensure a tight fit, preventing leaks and ensuring the integrity of the filtration process.

- End Caps and Core: These parts provide additional support and facilitate the flow of fluids or gases through the filter.

Specific functions of Safety Filter

The primary function of a safety filter is to remove impurities from fluids and gases, ensuring their safety for use in various applications. The specific functions include:

- Particle Removal: Eliminating suspended solids and particulate matter to prevent damage to downstream equipment and maintain process efficiency.

- Microbial Filtration: Removing bacteria, viruses, and other microorganisms to ensure the purity of the filtered medium.

- Chemical Filtration: Extracting harmful chemicals and contaminants to protect end-users and maintain product quality.

- Odor and Taste Removal: Particularly important in the food and beverage industry, where the sensory properties of the product must be preserved.

- Protective Filtration: Acting as a guard filter to protect sensitive equipment from contamination, thereby extending its lifespan and reducing maintenance costs.

Manufacturing process of Safety Filter

The manufacturing process of a safety filter involves several precise steps to ensure high quality and reliability:

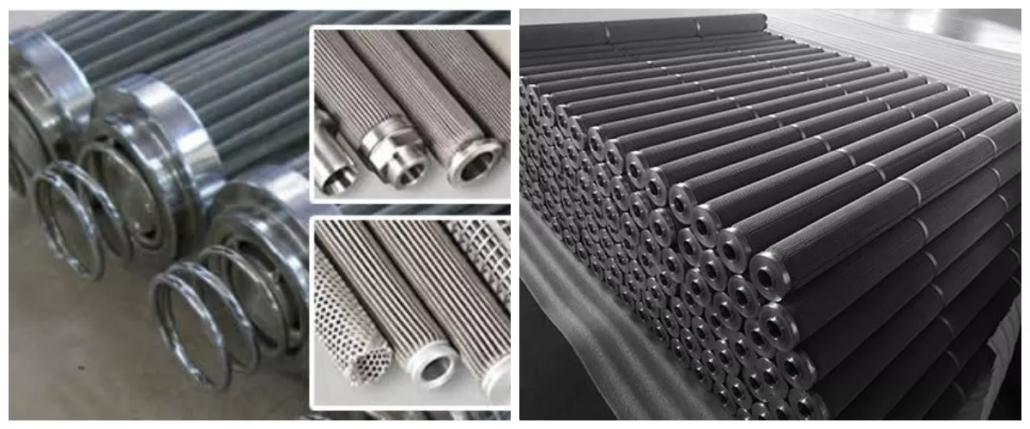

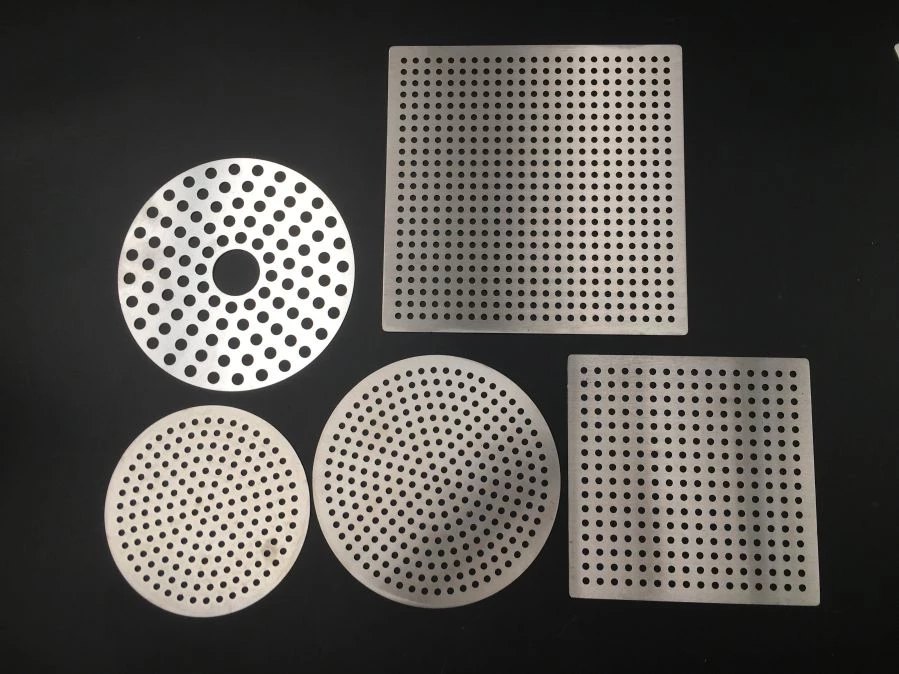

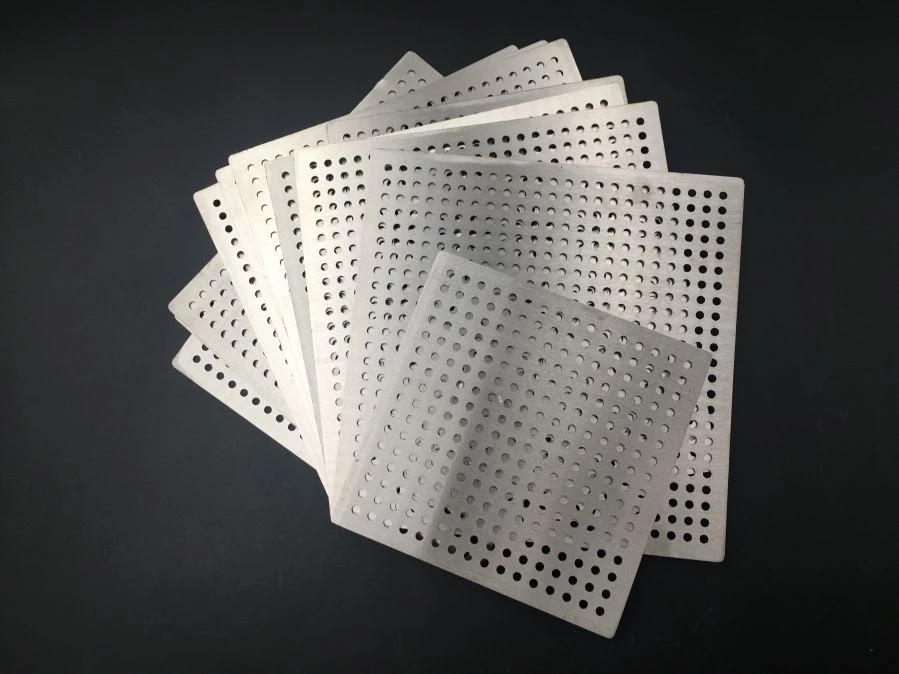

- Material Selection: Choosing appropriate materials, such as stainless steel or specialized filter media, based on the intended application.

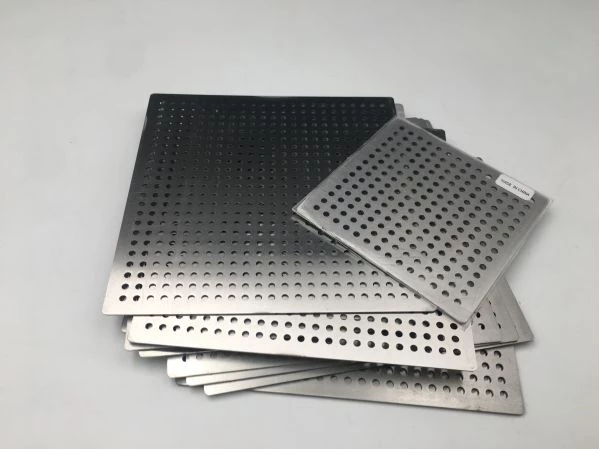

- Component Fabrication: Cutting, shaping, and forming the filter housing, media, and other components using advanced manufacturing techniques.

- Assembly: Carefully assembling the components, including installing the filter media and securing seals and gaskets.

- Quality Control: Conducting rigorous testing to ensure each filter meets stringent standards for performance and safety.

- Packaging: Properly packaging the filters to protect them during transportation and storage, ensuring they arrive in perfect condition.

Export Standards of Safety Filter

Exporting safety filters involves adhering to various international standards and regulations to ensure product quality and compliance. Some of the key standards include:

- ISO 9001: A global standard for quality management systems, ensuring consistency and reliability in production.

- CE Certification: Required for products entering the European market, indicating compliance with health, safety, and environmental protection standards.

- FDA Approval: Necessary for filters used in food, beverage, and pharmaceutical applications in the United States, ensuring they meet stringent safety requirements.

- NSF Certification: Indicates that the filters meet public health and safety standards, particularly important for water treatment applications.

- RoHS Compliance: Ensures that the filters are free from hazardous substances, making them safe for use and environmentally friendly.

Safety Filter wholesale policy

Our wholesale policy for safety filters is designed to provide maximum value to our customers while maintaining high standards of quality and service. We offer:

- Competitive Pricing: Bulk purchasing options at discounted rates, making it cost-effective for businesses to invest in high-quality filtration solutions.

- Custom Orders: Tailoring filters to meet specific requirements, ensuring optimal performance for unique applications.

- Flexible Payment Terms: Offering various payment options to accommodate different financial situations and business needs.

- Fast Shipping: Efficient logistics and shipping processes to ensure timely delivery of orders, minimizing downtime for our customers.

- Customer Support: Dedicated support teams available to assist with product selection, technical queries, and after-sales service.

FAQs

What is a safety filter?

A safety filter, also known as a security filter, is a device used to remove contaminants from fluids and gases, ensuring their safety and purity for various applications.

How does a safety filter work?

A safety filter works by trapping contaminants in its filter media, allowing only clean fluid or gas to pass through, thereby protecting equipment and ensuring product quality.

What industries use safety filters?

Safety filters are used in a wide range of industries, including water treatment, pharmaceuticals, food and beverage processing, and industrial manufacturing.

Can safety filters be customized?

Yes, safety filters can be customized to meet specific requirements, ensuring they provide optimal performance for unique applications.

What materials are used in safety filters?

Safety filters are typically made from durable materials such as stainless steel and specialized filter media designed to handle various types of contaminants.

Custom your Safety Filter from our factory

At our factory, we offer custom safety filter solutions tailored to meet your specific needs. Whether you require a high-security filter for industrial applications or a protective filter for water treatment, we can design and manufacture a product that meets your exact specifications. Our team of experts will work closely with you to understand your requirements and deliver a custom filtration solution that ensures the safety and purity of your fluids and gases. Contact us today to learn more about our custom safety filter options and how we can help you achieve your filtration goals.